Have you heard about the Advance Shipping Notice (ASN) or EDI 856?

This document presents essential data about a pending shipment. The goal of an ASN is to notify the buyer that delivery is on its way as the most basic. It includes details like when an order was shipped, what items, and the quantity of each item. It contains attributes of the shipment, such as the number of boxes, weight, package description of the units within the delivery, shipments method of transport, and information about the carrier. It is a critical document that can be used for order management and record clarity, smooth-running the supply chain, promoting productivity, and satisfying customer expectations.

The EDI 856 is a current compliance record based on the Accredited Standards Committee (ASC) X12 format – the common EDI standard used in the U.S., as defined by the American National Standards Institute (ANSI). Its use is to provide advanced notice to a buyer about a pending shipment of items.

How ASN Works?

As specified earlier, ASN functions in many ways. It provides an estimated time of arrival, so the buyer knows how to manage the staff who will assist in the unloading process. Once it arrives at its end, it permits barcode scan receiving, which initiates fast off loading and sorting of items. ASN is also used to support with preparation for flow-through or storehouse allocation from receiving to the shipping location and the end customer. If it will be delivered directly to the buyer, it presents the tracking number from the courier.

ASN is not just a document verifying that a delivery is on the way; it is an informative reference and a time saver. ASNs are beneficial when it comes to receiving deliveries, offloading trucks, and managing inventory. Before an order is shipped, Sellers attach barcodes on the boxes, and cases, and add that data on the ASN. When the delivery arrives, EDI 856 uses the data to confirm the shipment of each item. Method is as effortless as scanning boxes as they come off the truck, or could be as manageable as scanning a single barcode to take the entire contents. ASN also allows easy classification of errors.

Sellers that practice just-in-time (JIT) inventory systems expect the ASN to bring out that strategy. In which sellers order just as much of a product that they need, at the time demanded. Advanced shipping notices indicate when delivery of items is moving and coming or if there is a delay in the shipment.

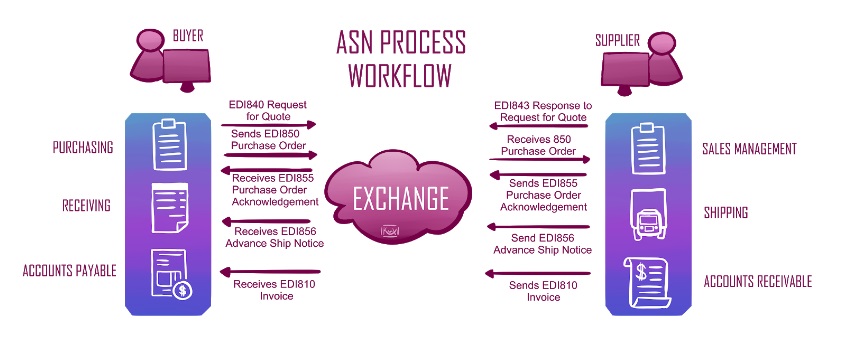

If both buyer and seller use electronic data interchange (EDI) systems, this exchange of data can happen automatically without the use of papers, emails, or encoding in the system one by one. Without ASN, the buyer tends not to know the quantity of the items that the seller will ship or when it arrives. If you don’t have EDI, the ASN is not as capable, and the right people might not receive the correct shipping information when it is needed, and human error to record incorrectly may happen.

ASN Structure

Shipment-Order-Item (S-O-I)

They are used for a primary Ship Notice/Manifest, not including UCC-128 or GS1 label information.

Shipment – Order – Tare – Pack* – Item (S – O – T – P – I)

Known as the “pick and pack” process – used when there is a label in a carton (UCC-128 or GS1), and there are various products shipped together on a pallet. If labeling is order specific, this process is used. But if no Tare (pallet) details are needed on the “pick and pack” process, we use S-O-P. S-O-T-I is used if no Pack (carton) details are needed on the “pick and pack” process. And we use S-O-T-O-I if both pallet and pack details are needed on the “pick and pack” process.

Shipment – Tare* – Order – Item (S – T – O – I)

Process used if UCC-128 or GS1 labeling is needed, and if order specific label is not required. Multiple orders on a pallet will have one label per pallet. The label per order will not be separated.

Shipment – Order – Item – Tare* (S – O – I – T)

Usually called the “standard carton” process—adequate description of shipment of a single type of product on one or more pallets.

Purpose

The purpose of the ASN comes from receiving it before the actual delivery. Tends to impact the logistics stream in three “C’s”: Cost, Correctness, and Compliance.

- Cost – Today’s generation, receiving systems are fast-moving that there is not enough time to get the breakdown cases for manual receipt or confirmation of contents against paperwork. Preferably, these systems depend on barcodes scanning from shipping labels. Advance Shipping Notice that includes Serial Shipping Container Codes (SSCC) provides contents of each pallet, including the Global Trade Item Number (GTIN), tie in with Batch/Lot Numbers, and the quantity of each GTIN and Batch/Lot Number combination on the pallet. It greatly enhances the speed of the receiving process as obtained from reading the SSCC from each pallet can be matched to the data previously sent in the ASN. Receiving costs can be reduced by at least 40 to 50% when using ASN.

- Correctness – When ASN is received, it will immediately inform any difference between what the order was, and what was shipped.

- Compliance – Having the delivery details ahead of receiving the orders allows the buyer to administer the items beforehand.

Benefits

- Reduces paper-based processes

- Allows automatic capture of the GTIN and Batch/Lot Numbers of each case

- Guarantees efficiency between product shipped and received

- Lessens unloading time at the warehouse

- Supports the drop-shipping process

- Supports advance order allocation

- Supports integration of data to different systems with single data entry

- Supports flexible management of schedule by the receiver

- Supports planning of space allocation for item dispatch

- Provides efficient payment process by facilitating accurate matching

- Enhanced order cycle times

- Higher in-stock rates

- Enhanced inventory cycle